Empowering Energy Leaders:

At UEST, we foster impactful collaborations and strategic advice to governments, global corporations and institutions, amplifying their progress as energy pioneers. We design solutions for underground energy storage (hydrogen, natural gas, carbon capture, geothermal). We collaborate to identify future success criteria, frame necessary developments, and maximise resource efficiency.

We bring broad expertise covering all segments (subsurface, surface, transportation, logistics, operations, legislation, procurement, project management), ensuring a holistic approach to meet your requirements. We know the limitations of standalone and silo-type projects that fail to deliver real value. Focused on the facts and driven by technical expertise, we bring unmatched proprietary data and insights to help clients make informed decisions and create value.

Why choose UEST?

By choosing to partner with us, energy leaders gain access to:

Strategic advisory and holistic assessments

Centre of

Excellence

Long-term partnership & value creation

How We Help Clients

We analyse the project’s potential from different perspectives: Methodology, geological, technical, economic, legal, financial, and regulatory. We support your project throughout all stages, from identification, framing, screening, procurement, project management, execution and commissioning.

We understand your challenges and provide strategic guidance.

We have been building models for many years without getting anywhere. These models were good to play with but do not provide answers."

We are undertaking one study after the other but are not progressing to a solution to our problem.”

Work was performed by very experienced experts with excellent integration between disciplines. Really outstanding.

I would like to have such a representative reservoir model as you have developed for each of my fields.

We have implemented your recommendations in the field. The new production wells added 5% to your forecasted oil production. This is unimaginable for a P50 case. Congratulations to your work!

You have done a fantastic job for us. Even though this project was carried out in difficult conditions during the pandemic in 2020-2021, you were able to deliver high quality work with very limited delay on the planning. Your work serves as reference for our company.

You built our underground storage model 10 years ago. We are still using it for our reservoir management and gas sales contracting. Incredible!

You have analysed several of our reservoirs. Work, results, and recommendations were perfect for us and helped us move forward with field re-development. Your staff was way beyond our expectations. We hope you will continue supporting us.

Our organisation builds on decades of expertise and offers a well-rounded service portfolio covering key underground energy sectors

UNDERGROUND

GAS STORAGE

(UGS)

UNDERGROUND

CO2 STORAGE (CCS/CCUS)

UNDERGROUND

HYDROGEN STORAGE

GEOTHERMAL

ENERGY

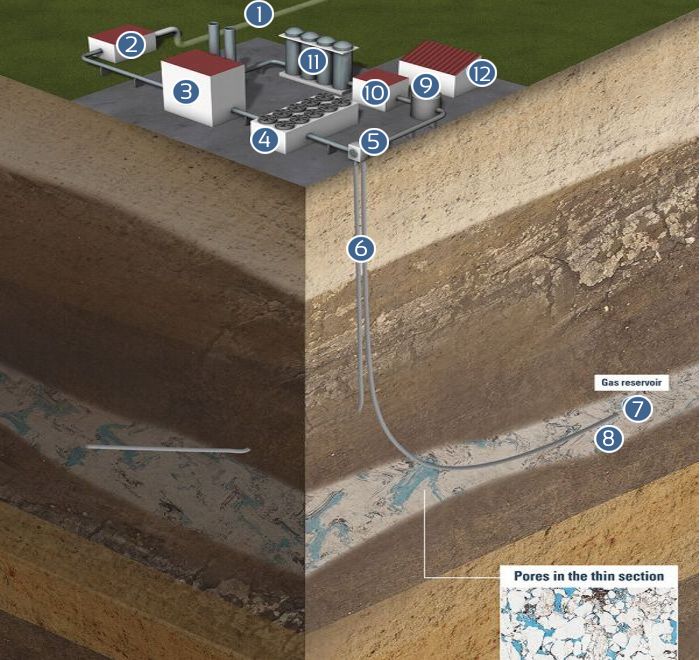

Over the past 30 years, we have supported our customers in converting gas and oil reservoirs into underground gas storage (UGS) facilities and have advised them in extending the capacity of their UGS operations to cope with the increasing, yet fluctuating, seasonal energy demand.

Our extensive reservoir and well engineering expertise, combined with our drilling and workover capabilities and our operational experience with developing numerous gas storage surface facilities, from concept to handover, have made us the preferred partner and trusted advisor for gas storage companies all over Central Europe and beyond, among these Europe’s leading storage facility operators.

How do gas storage facilities work?

Underground CO2 Storage

(CCS / CCUS)

Carbon Capture, Storage (CCS) and Utilisation (CCUS) are important emission reduction technologies and can help to scale up the hydrogen economy (Blue & Green Hydrogen).

CCS/CCUS technologies involve the CO2 storage deep underground in geological formations, i.e. aquifers and depleted hydrocarbon reservoirs.

Depleted gas reservoirs represent a great opportunity for underground CO2 storage as they provide significant storage capacity and infrastructure in place.

Our extensive reservoir, well engineering and surface facilities expertise, combined with our experience from developing many gas storage operations, makes us the preferred partner for operators planning underground CO2 storage facilities.

We have adopted a robust workflow starting from identifying CCS opportunities to maturing these to underground CO2 storage projects.

Underground Hydrogen Storage

STORAGE

Hydrogen will play a key role in a clean, secure and affordable energy future.

Green Hydrogen, produced by electrolysis of water and powered from renewables, is the long-term and low/zero-carbon way to produce hydrogen.

Blue Hydrogen, produced from fossil fuels and combined with underground CO2 storage (CCUS, CCS), will help to scale up the hydrogen economy and bridge the gap between Green Hydrogen and those methods currently dominating hydrogen generation.

Hydrogen storage is an important cornerstone for smooth operations of a hydrogen economy.

Underground (geological) storage in depleted gas and oil reservoirs, aquifers and salt caverns appears to be the best option for large-scale and long-term storage while securing a continuous and well-defined supply stream.

Benefit from our experience. Starting from our initial assessment of reservoir and facilities, we deepen your knowledge base through laboratory experiments, special studies and numerical modelling.

Our extensive reservoir, well engineering and surface facilities expertise combined with our experience from developing many gas storage operations, makes us the preferred partner for operators planning hydrogen storage facilities.

Geothermal Energy

Geothermal energy is abundant, renewable and with minimal carbon footprint. It has the potential to significantly contribute to the global energy supply.

We support our customers in identifying locations of high-quality geothermal resources, in mitigating geological risk and in designing and developing geothermal projects.

We have planned, drilled and completed many dedicated geothermal wells for our European clientele.